Metal inventories, we have a problem

Copper anticipated 428kt deficit vs 260kt of current visible stock

global metal inventories historically tight

metals supply tight, demand resilient, supply chains disrupted, stimulus incoming

some metals impacted more than others, in particular, copper

🚀 Please smash the ♡ button, subscribe for the banter ✓ and share with friends and colleagues. We are always grateful for your comments and support.

Metal stockpiles across the world have fallen precipitously for the last ten years and, although some have stepped back from the edge in recent months, many remain historically tight:

the London Metal Exchange's (LME) global warehouse network held 654,345 tonnes of metal at the end of 2022, the lowest inventory on record since 1997; by December 2023 this had risen to 1,163,830 tonnes

Goldman Sachs warns of “an anticipated 428kt deficit set against just 260kt of current visible [copper] stock”, it’s tightest since 2021

an indication that off-exchange inventories are tracking official exchanges, some smaller operators have withdrawn their services to the LME and warehouses and sold up to specialist logistic companies, with the number of LME’s registered warehouse units falling from more than 600 to 453

Is there a moment when such tight stockpiles becomes a problem for global metal supply?

Why are global metal stockpiles so low?

There are a number of significant factors for the drawdown in inventories:

expectations and management of an economic downturn and consequent fall in commodity demand

high interest rates and a strong dollar generally mean lower commodity costs and higher costs associated with holding the inventory

For example, China’s real estate market, one of the major drivers of the last metals commodity supercycle, has been in a significant downturn for the past two years.

And they’re not the only ones. Germany construction sector has seen it’s first decline in 2024 since the financial crisis in 2009. Global PMI (Purchasers Managers' Index) is down across the developed world.

So, at first glance, it's a classic downturn with logically lower inventories.

But are stockpiles too low?

There are four main factors we warn could lead to a significant whiplash in prices:

financial stimulus and the energy transition

national stockpiles

geopolitical crisis, export restrictions

tight supply, resilient demand

"Higher rates led to depletion of inventories, financially, physically. Spare capacity outside of oil exhausted and bottom line is are these interest rates really doing that much? You’ve got a booming US economy, record demand across many of these different commodities and I do not understand where the bearishness is coming from. The sentiment, the positioning, you’d think we’re about to run off a cliff, but the reality is good old mid-cycle pause. We just took our breath, big rate hikes, inventories depleted , spare capacity exhausted, super high demand levels, growth beginning to recover again. Isn’t that the classic end of cycle playbook to be long commodities?

I think 2024 we’re going to see it happen quickly."

— Jeff Currie, Partner Alumnus, Goldman Sachs, commodities veteran

Financial stimulus and the energy transition

Let's start with the big one: China.

We're under few illusions about the difficulties facing China's economy, however, the country's demand for many commodities remains resilient.

For example, China has imported record amounts of oil, coal, copper ore and iron ore in 2023. In particular, imports of copper ore and concentrate hit a record high of 27.54 million tons in 2023, up 9.1% from 2022.

While there has, so far, been no "big bazooka" financial stimulus by China's authorities, there has instead been a steady stream of fiscal support. Just a few examples: the central bank provided US$112 billion in one-year loans in December, and authorities are now reportedly considering US$139 billion of Special Bonds. And most recently, reports that China is considering a US$278 billion rescue package.

Authorities want to shift China's economy from property construction to energy transition manufacturing. For example:

electric vehicle sector is projected to contribute 1.8% to China's economy in 2024, up from 1.2% in 2022

after investing over US$130 billion into the solar industry in 2023, China is estimated to hold more than 80% of the world’s polysilicon, wafer, cell, and module manufacturing capacity from 2023 to 2026

All this while construction in the country saw an uptick in growth at the end of 2023.

And it's not just China.

India is forecast to defy global economic headwinds and remain the world’s fastest growing economy in 2024, with a planned US1.4 trillion investment in infrastructure over the next five years.

And, across the West, trillions in stimulus to boost growth in the energy transition sectors are being rolled out:

since the US Inflation Reduction Act passed in 2022, US$408 billion in domestic utility-scale clean energy investments have been announced

the EU Green Deal Investment Plan aims to mobilize US$1.1 billion to meet it's net-zero targets

All of which has a corresponding impact on critical metals demand.

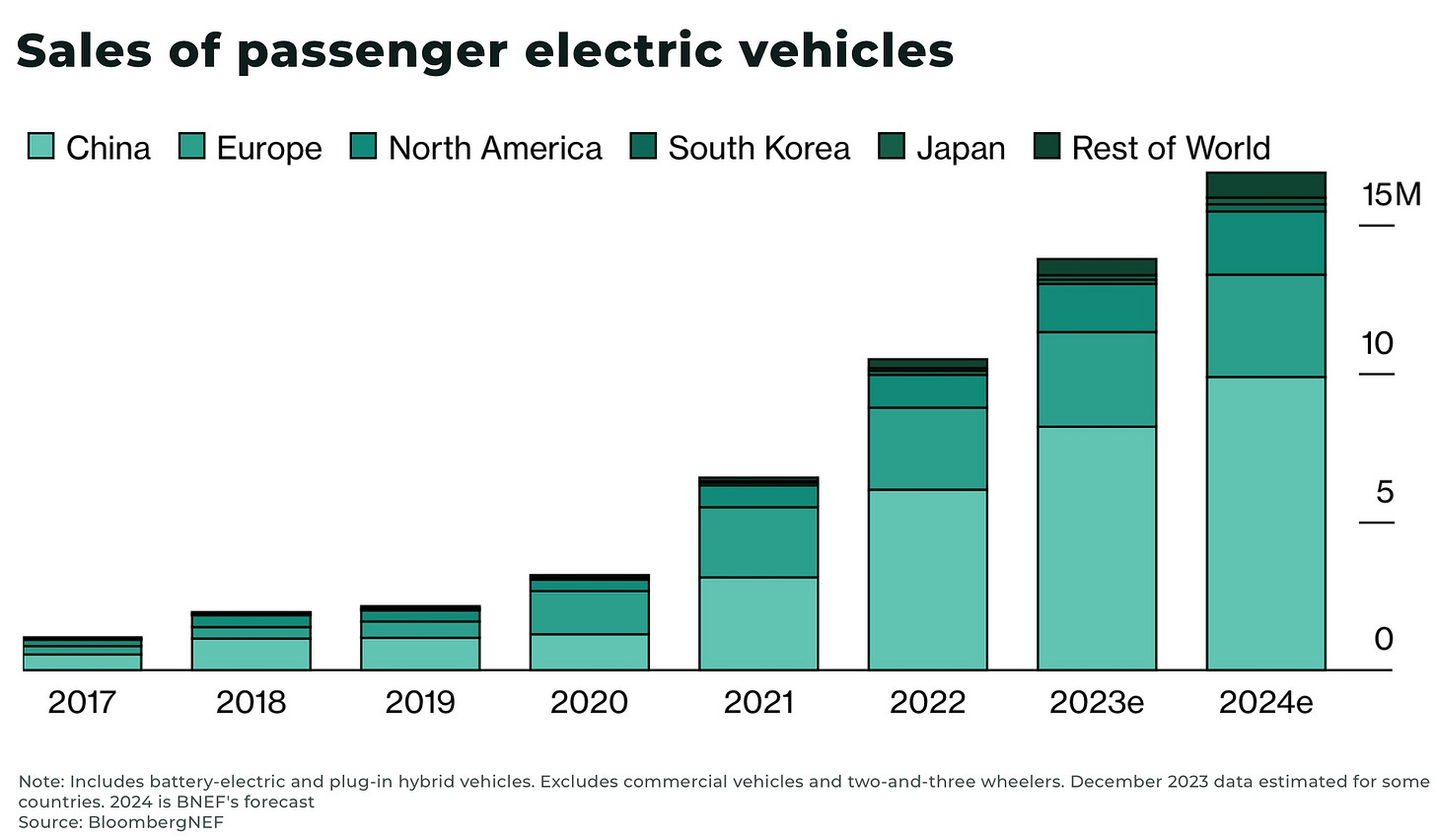

For example, electric vehicles (EVs) need x6 more critical minerals than internal combustion engines, and growth of EV sales is estimated to increase by 21%, 16.7 million, in 2024.

National stockpiles

Governments are also proposing to build strategic reserves of critical minerals:

in France, President Macron has announced the imminent launch of a “major inventory of mining resources”, including a US$2.17 billion fund for critical minerals

the EU's new Critical Raw Materials Act (CRMA) sets the stage for a potential strategic stockpile, as it requires member states to report existing stocks before deciding on needed levels of any EU wide stockpiles

in the US, a research paper for Congress warned:

"As of April 2023, current NDS inventory mitigates less than half of estimated strategic and critical materials shortfalls for military requirements; less than 10% of essential civilian demand shortfalls; and approximately 6% of total net shortfalls in “base case” national emergency scenario" — Emergency Access to Strategic and Critical Materials: The National Defense Stockpile

In 2022, the Department of Energy, Department of Defense, and Department of State agreed to set a foundation for a critical minerals stockpile to support the US transition to clean energy and national security needs.

At least US$1 billion has been approved for the appropriation of critical minerals and other essential commodities for the National Defense Stockpile (NDS)and, while no exact figures are publicly available, there are signs China's Strategic Reserve Bureau are also starting to stockpile some strategic critical minerals, such as cobalt

One estimate, by Goldman Sachs, suggests if the US and EU were to copy the target of 3 month's commodity import volume cover by the US Strategic Petroleum Reserve (on oil) onto critical minerals, it would represent:

EU: building a regional stockpile of 250kt of refined copper and 1.4Mt of primary aluminium

US: building stockpiles of 180kt of refined copper and 1Mt of primary aluminium, respectively

Geopolitical crisis, export restrictions

One of the major drivers behind governments seeking a national stockpile is increased geopolitical tension between critical mineral exporters and importers, especially China and the US.

As we highlight in our recent analysis — The canary in the gallium and germanium mine — China's export restrictions on gallium and germanium, as well as graphite and other rare earth technologies, are sounding alarm bells in the West, who in turn are introducing their own import restrictions.

The reason: the US identified 50 critical minerals in 2022, but was 100% net import reliant for 12, and had a net import reliance greater than 50% of apparent consumption for 31 others.

As we warn in the piece:

Secure supply chains for critical minerals in the West are years, if not decades away.

China has chosen gallium and germanium as their warning shot, and they will be watching closely to see how the West responds as supply tightens.

Similar to the rising carbon monoxide in the coal mines of old, will the canary fall over dead, or find enough air to breath and live to fight another day?

Tight supply

Supply across a significant number of critical minerals is already tight due to years of ongoing underinvestment and permitting, as well as community protests in places like South America — just as demand is expected to soar as countries try to meet their net-zero targets.

This is compounded by problems in global supply chains that are adding significant delays and complications to delivery schedules:

First there was Covid-19 and the subsequent national lockdowns, then the war in Ukraine and sanctions, and now renewed difficulties in shipping as traffic through the Panama Canal — approx 40% of US container traffic — is backed up due to droughts and tanker trips through the Suez Canal — approx 10% of world trade — are set to drop by 66% in January 2024 due to Houthi attacks. All of which has meant a drawdown on inventories.

Conclusion

In other words: primary supply is already tight in many metals, just as governments are rolling out financial stimulus for energy transition sectors, introducing import and export restrictions on critical minerals, while at the same time upping national stockpile requirements — at a time when it takes longer and longer to ship commodities across the globe. And metal inventories are tight.

An eventual, steady return to growth, with investment in critical mineral supply in line with demand expectations, and a general re-stocking, means there should be no problem. This is all part of the course of a normal economic cycle.

But, if something unexpected happens or breaks in the chain outlined above, for example a bigger stimulus package in China or lower interest rates in the US, then low inventories mean any supply crisis will be immediately acute.

Now, not all commodities and critical minerals are equal, from oil and the SPR, to uranium to gallium, some would be effected more than others depending on the scenario. For example, barring some very significant shock, we expect nickel inventories to rise throughout 2024.

Copper is perhaps one of the most vulnerable metals to an acute inventory shock:

Goldman Sachs warns of “an anticipated 428kt deficit set against just 260kt of current visible [copper] stock”

tight supply, especially after the halt of copper production from First Quantum's mine in Panama, as well as lower copper output guidance for 2024 by Anglo American and Vale

growth in world refined copper usage forecast to increase to a growth rate of 2.7% in 2024, from 2% in 2023

Fastmarkets, for example, forecast a deficit of around 300,000 tonnes of copper concentrate for the year

and, in China, the world's top metal consumer, copper inventories in major consuming regions stood at 71,600 tons after the new year holiday, a near 14-year low, according to Shanghai Metals Market (SMM)

This means, rather than a traditional commodities supercycle driven by a major demand factor, such as in the 1970s when the dollar depreciated or in the 2000s after China joined the WTO, it is crucial for investors to be aware of commodity-specific drivers and potential problems in order to navigate this volatile market.

Always insightful metal and mining commentary from The Oregon Group.