Is there enough tin supply to hold the tech revolution together?

Without tin solder there is no semiconductor industry or energy transition

🚀 Please smash the ♡ button, subscribe for the banter ✓ and share with friends and colleagues. We are always grateful for your comments and support.

Often overlooked, tin is listed as a critical mineral in the US for good reason.

More than 50% of tin is used as solder in circuit boards, essential for semiconductors, data centers, mobile phones, electric vehicle and batteries, as well as in solar panels — it is the solder that binds the technology revolution.

The International Tin Association estimates US$1.4 billion is needed to deliver 50,000 tons per year more tin by 2030, yet supply, instead of expanding, is tightening with global refined tin production in 2023 declining 2.1% from 2022 to 370,100t.

The challenge is that 90% of reserves are located in regions where geopolitical risk is ranked as high, in particular, Indonesia and Myanmar.

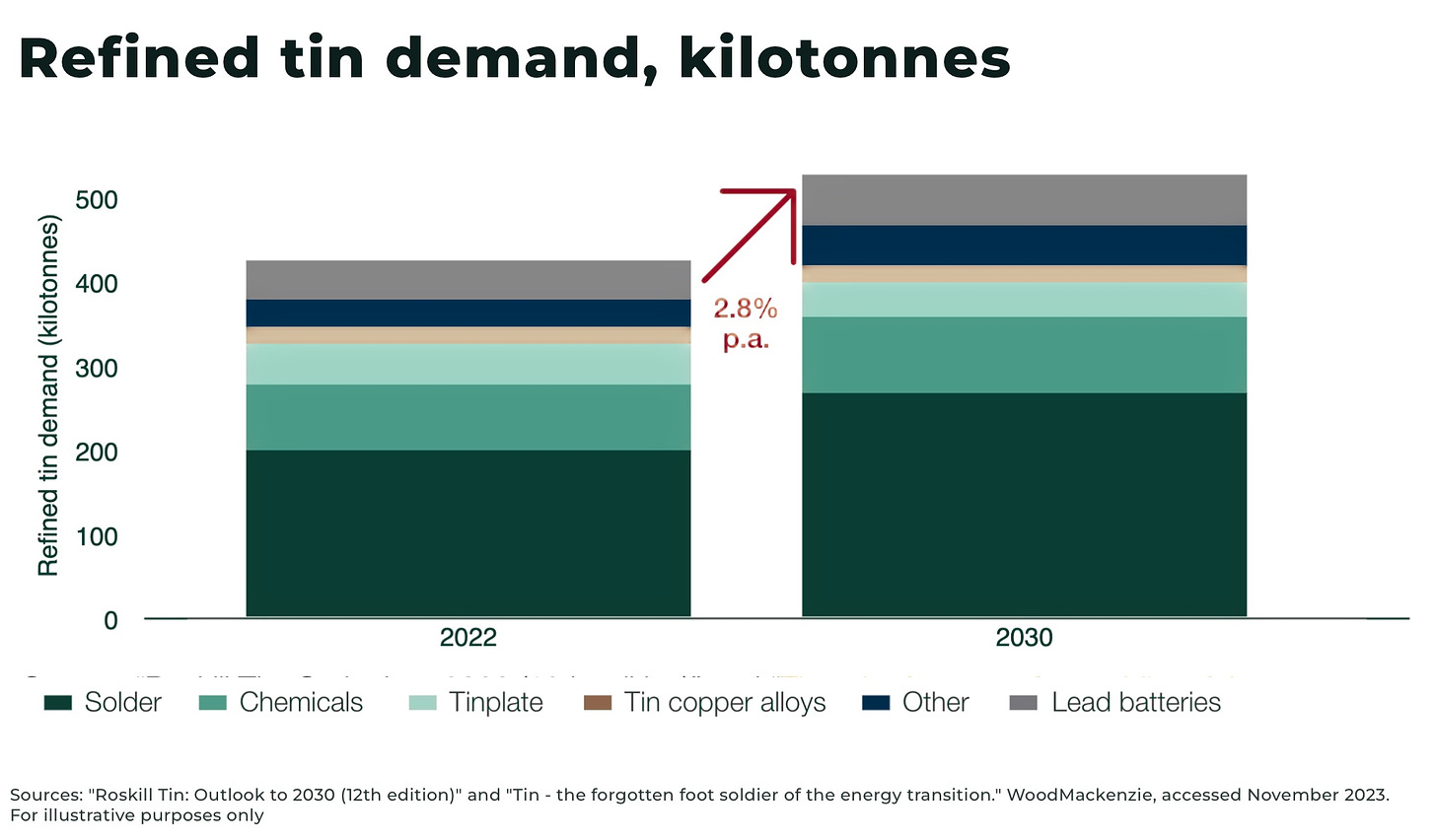

As uncertainty over the supply of tin increases, so the demand fundamentals look stronger than ever.

What is tin and where does it come from?

Tin is a malleable, non-toxic, silvery-white metal with a low-melting point that flows and bonds easily with other metals, making it ideal for soldering in electronics.

Other metals could, in theory, be used instead, but tin’s relative abundance and cost-effectiveness compared to, for example, silver and gold, mean there are few economically viable substitutes (and lead solder is heavily regulated as a hazardous substance).

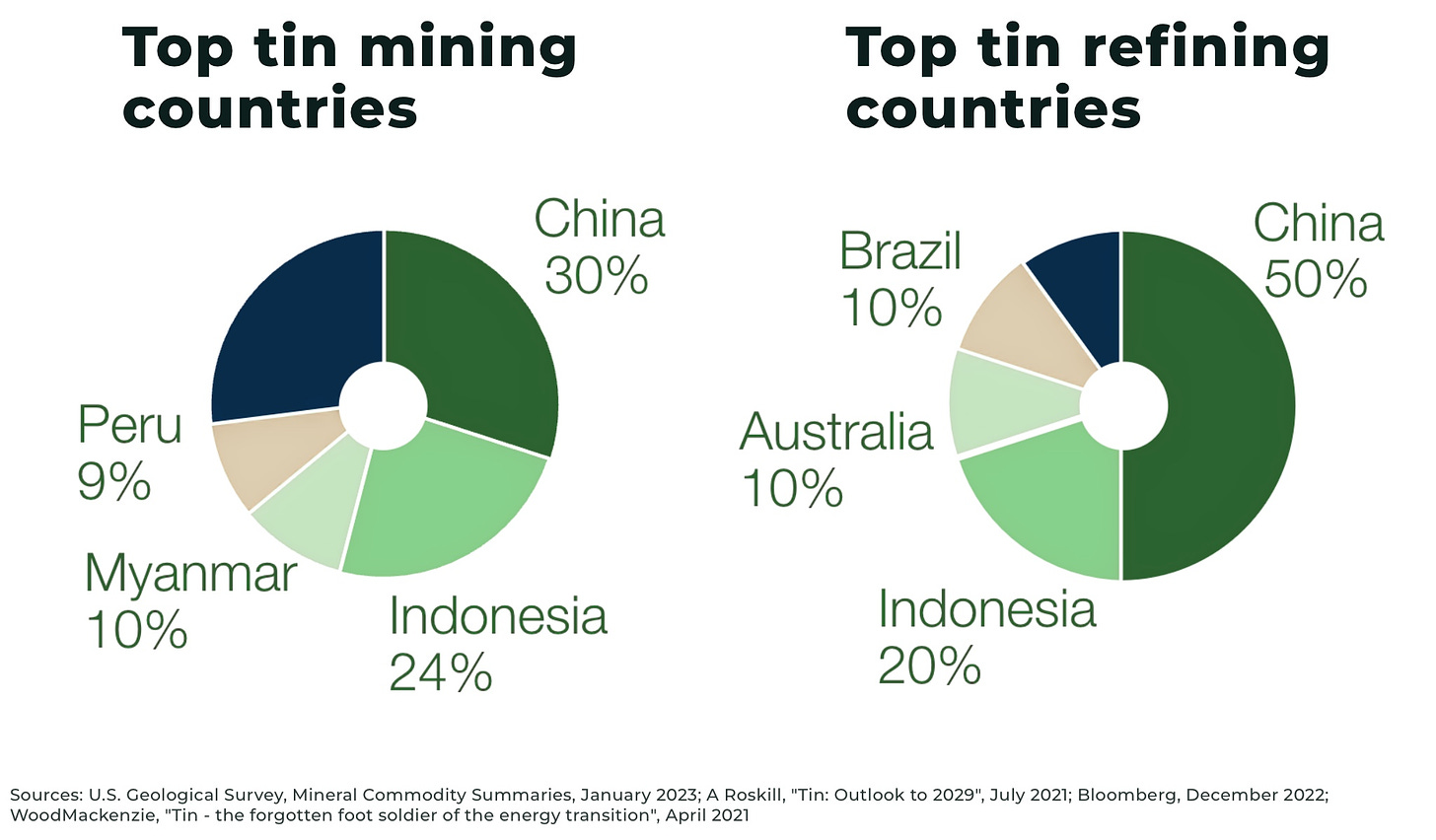

The major mining and processing countries are China, Indonesia, Myanmar, as well as Peru and Australia.

The size of the industry, relative to other major metals such as copper or nickel, is small, but its importance for current and future technologies, such as AI, as well as the “electrification of everything” in the energy transition, cannot be underestimated.

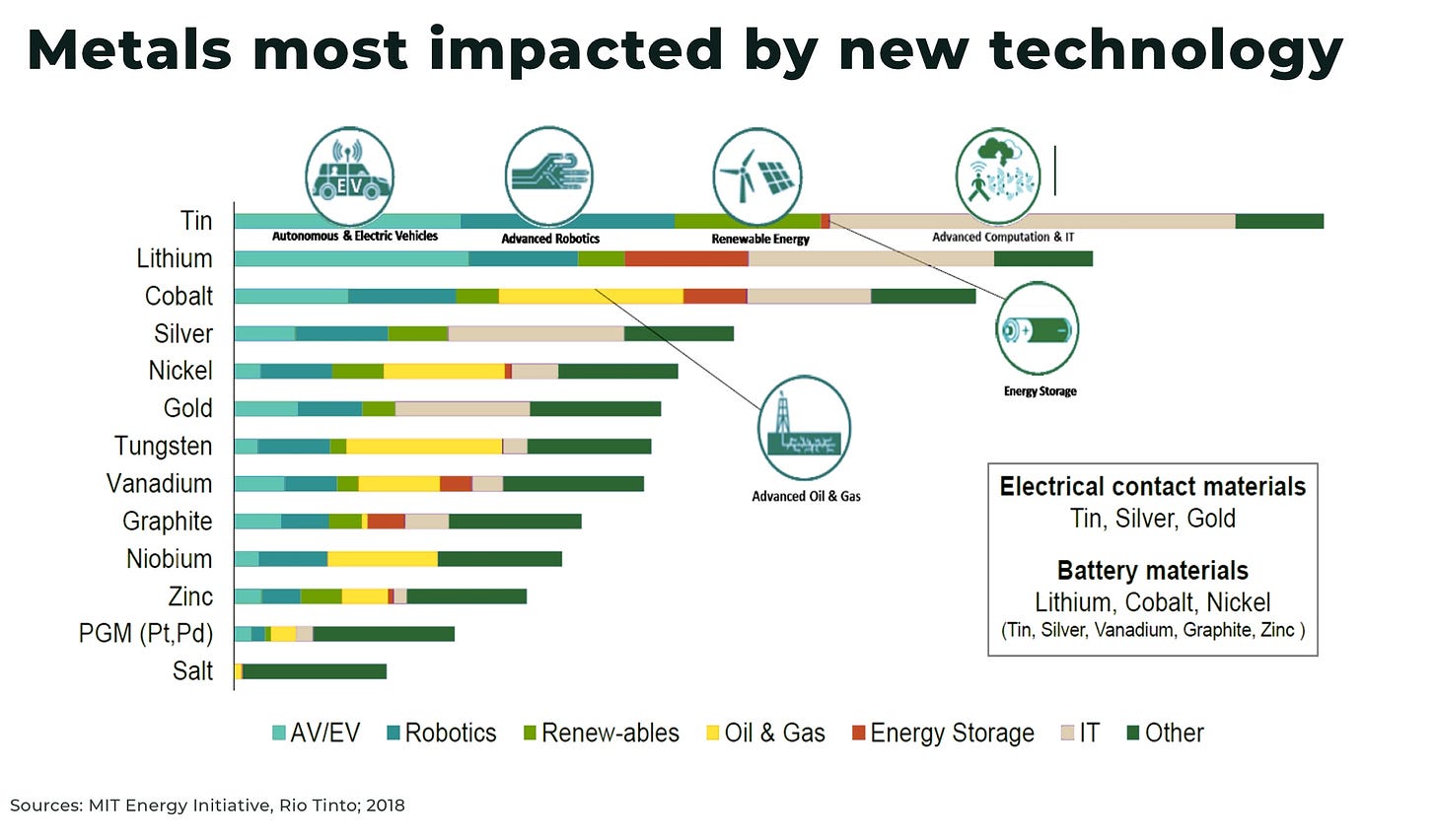

A 2018 study by MIT and Rio Tinto found that tin is the metal most impacted by new metals, for two main reasons:

the potential for increased demand applications particularly in the electrical and energy storage areas

because these demand changes might be fairly large in comparison to the current market size

Governments are starting to take note of the possible opportunities and challenges, for example, both Australia and Indonesia recently added tin to their national list of critical minerals.

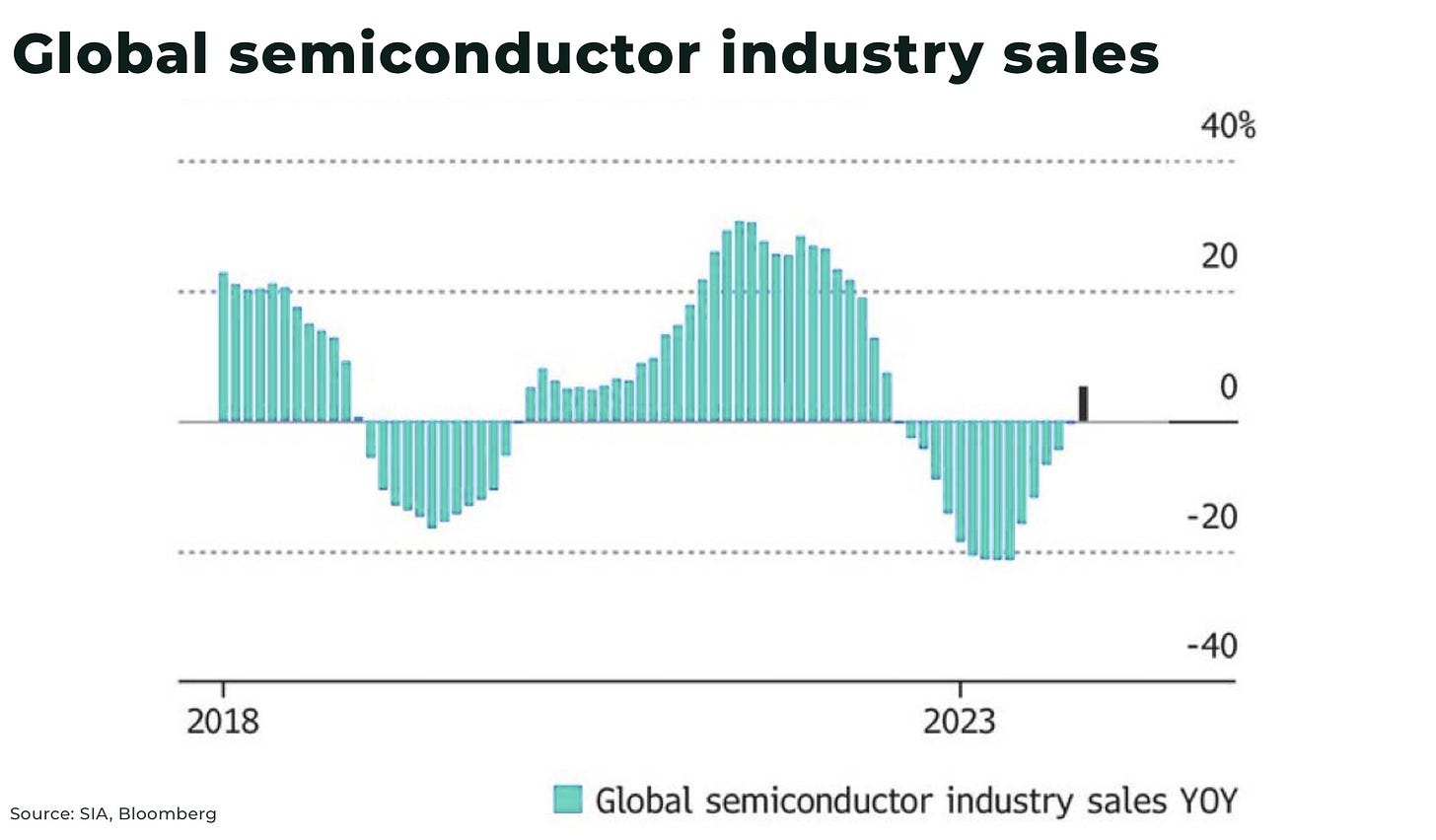

Semiconductors

Tin’s importance for semiconductors and electronics was highlighted during the Covid pandemic, when tin producers across Asia and South America were hit with lockdowns — output from the world’s top 10 tin producers fell by 13% between 2020-21 — but sales of consumer electronics soared as populations were forced to stay and work from home.

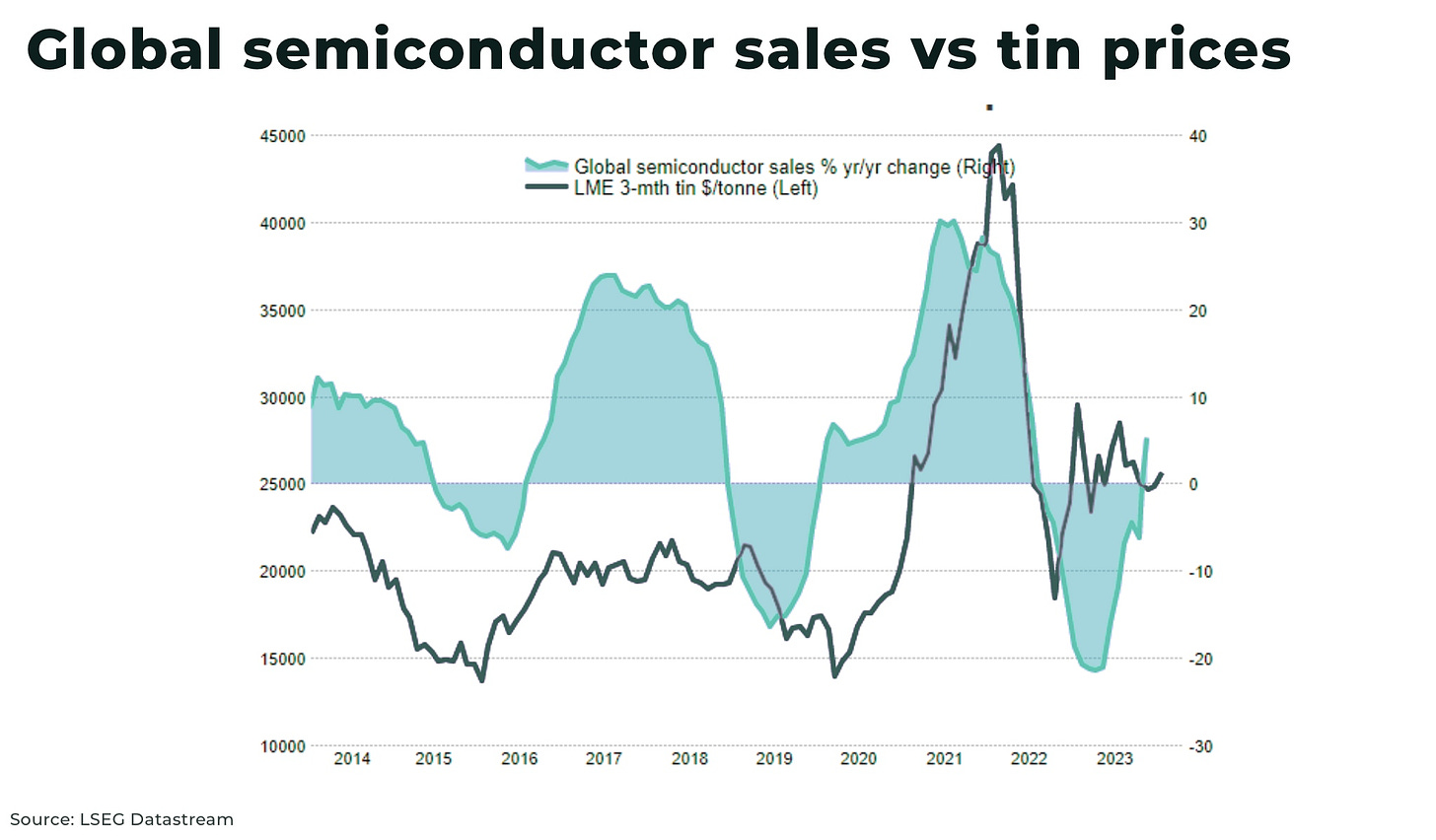

Global semiconductor sales are a good proxy for tin demand as solder. So, what does the future hold for demand?

Global sales of semiconductors are forecast to reach US$588 billion in 2024 — a 13% increase on 2023 and 2.5% higher than 2022’s record industry revenues of US$574 billion. This would have an obvious impact on tin demand.

The explosion of semiconductor demand driven by the Artificial Intelligence (AI) revolution is expected to only drive this demand higher. For example, NVIDIA’s CEO Jensen Huang says there is no way Nvidia can “reasonably” keep up on demand for its AI chips in the short term.

The Energy Transition

Solar power

Tin is essential for solar panels, as a “solar ribbon”, that is a copper wire coated in tin solder connecting each solar cell.

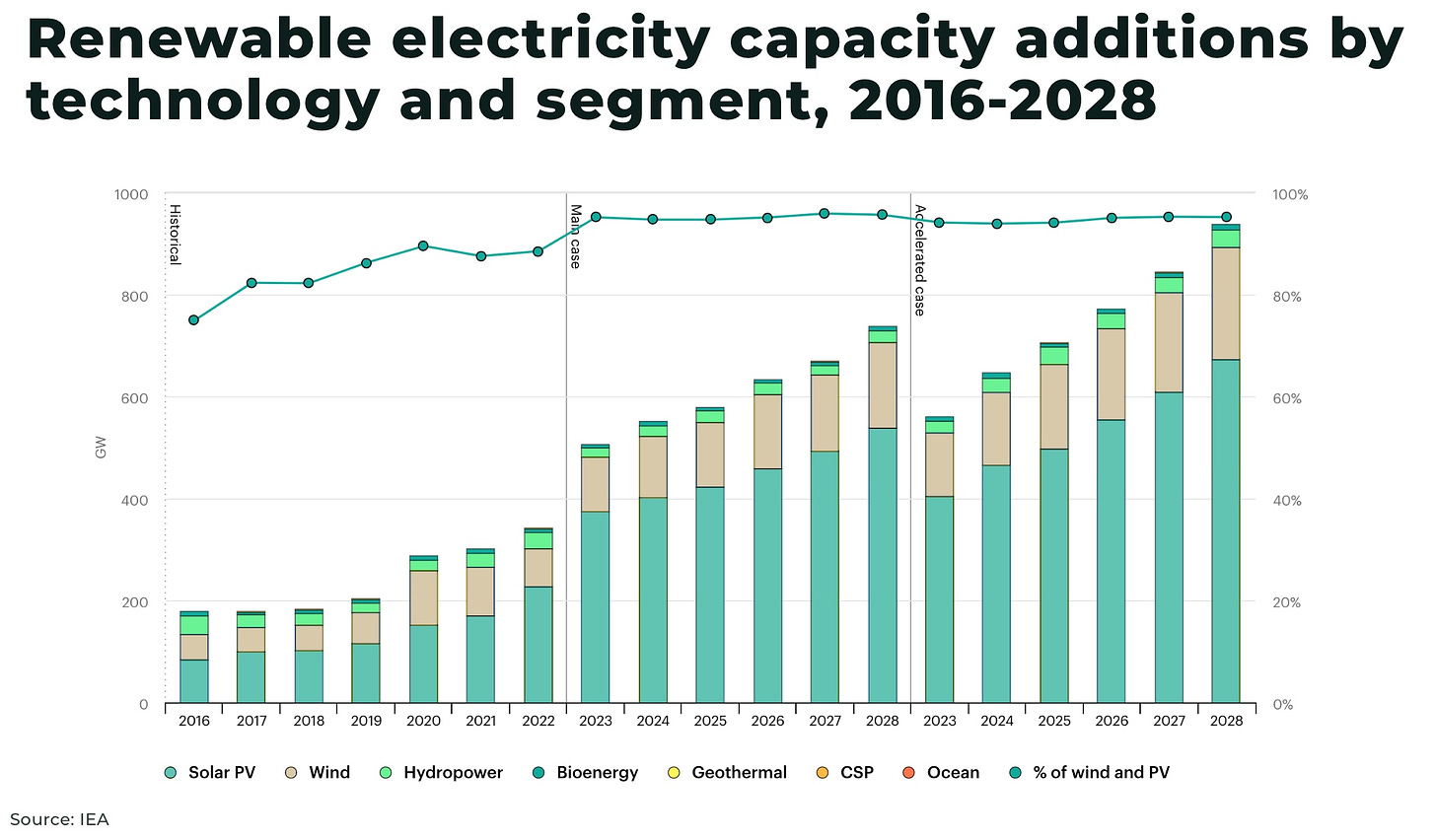

The International Tin Association estimates the solar industry used more than 22,000 tonnes of tin in 2022, growing x6 over the past 10 years to keep up with solar demand. And with IEA estimates that solar production could double by 2030, the use of tin in solar ribbon is expected to increase 14% to 55,000 tons per year by 2030.

Electric vehicles and the electrification of everything

It's not just solar power.

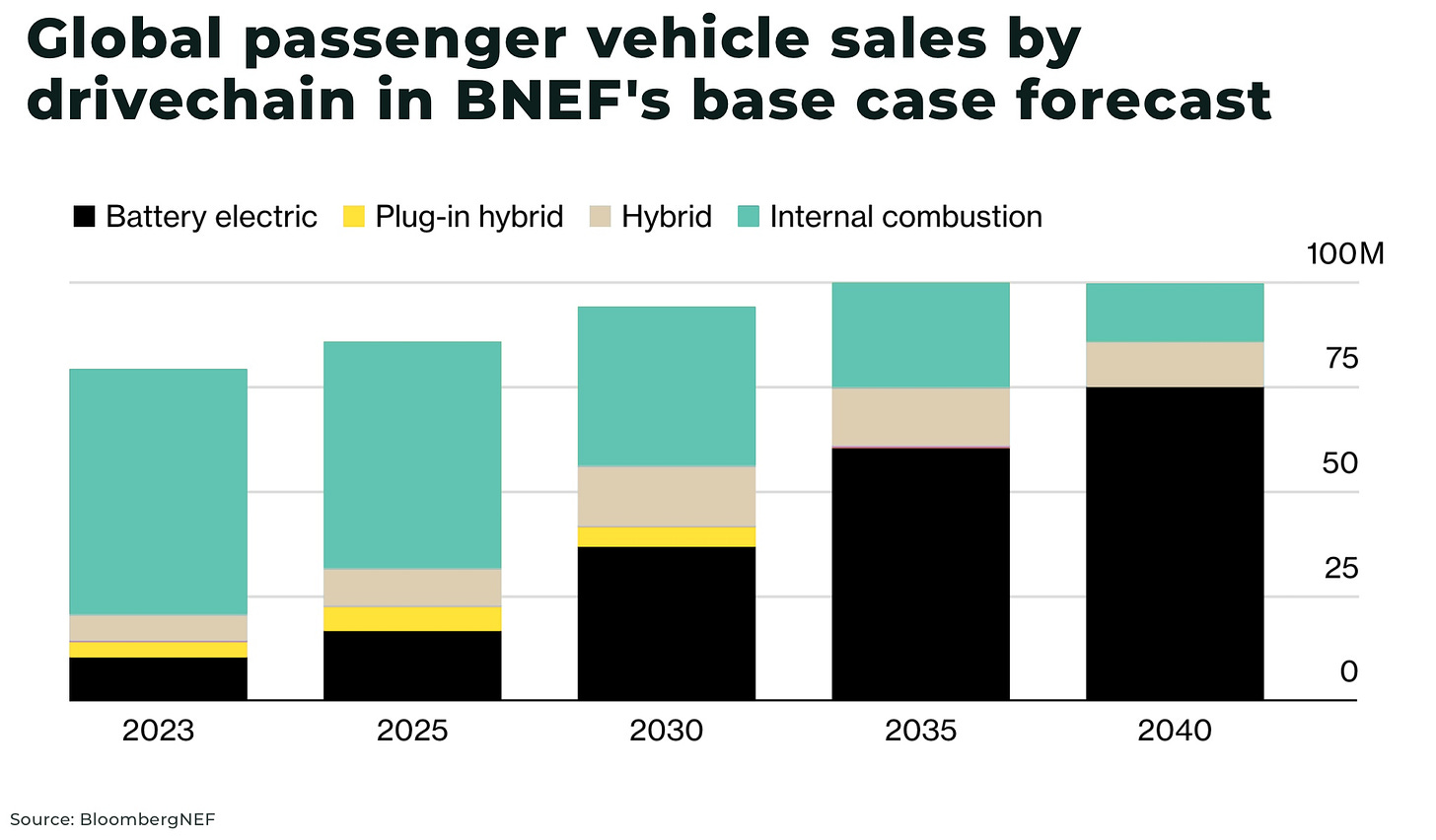

An electric vehicle (EV) uses an estimated x3 more tin than an internal combustion engine due to the significant increase in electronic components that need solder.

And EV sales are expected to hit US$8.8 trillion by 2030.

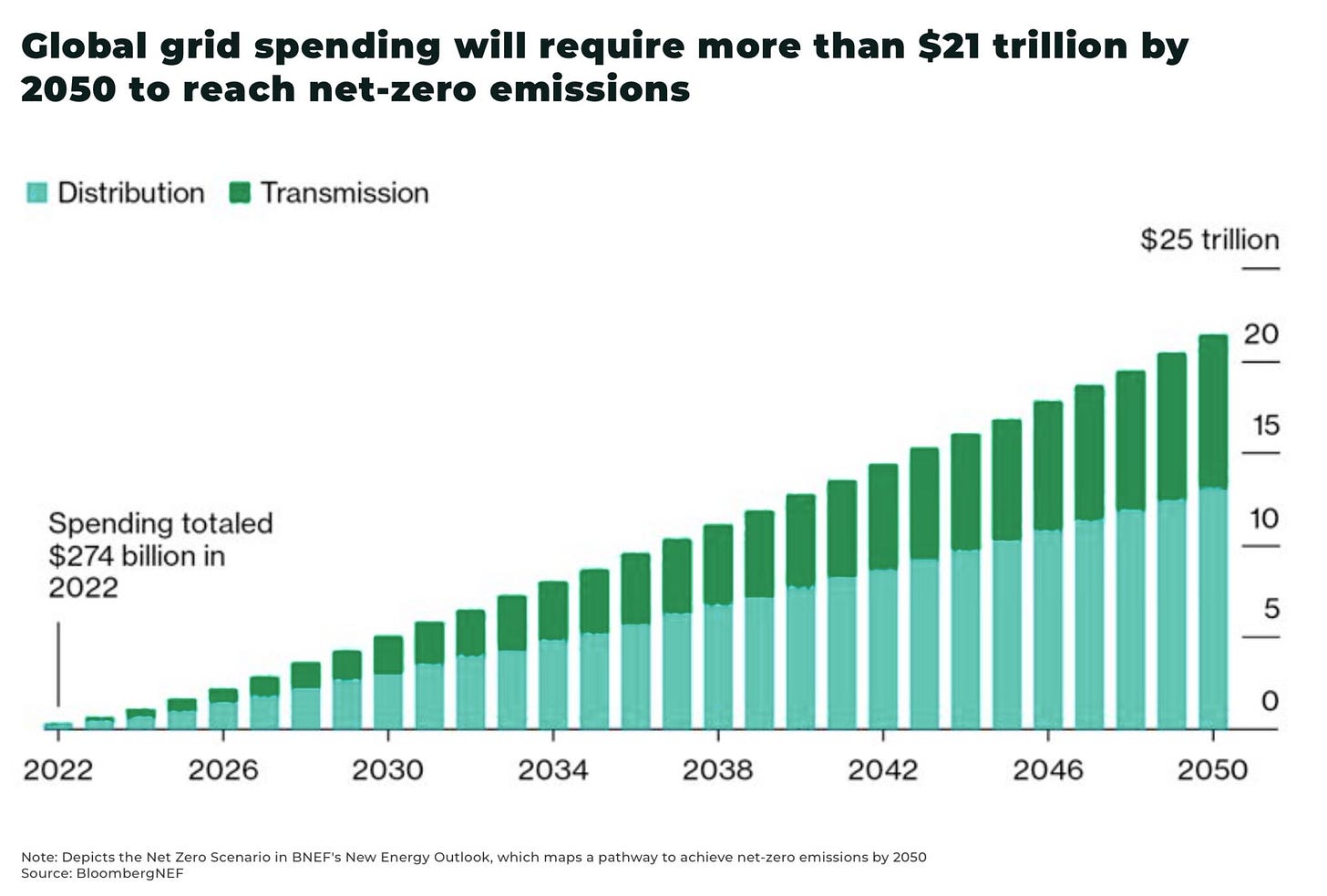

And it’s the same across the energy transition, with the “electrification of everything”, from wind turbines to expansion of electric grids, EV chargers to hydro energy.

There are no specific figures, for example, on how much tin is used in each wind turbine or in transformers across national electric grids, but to give context on the anticipated growth of this new demand on tin supply:

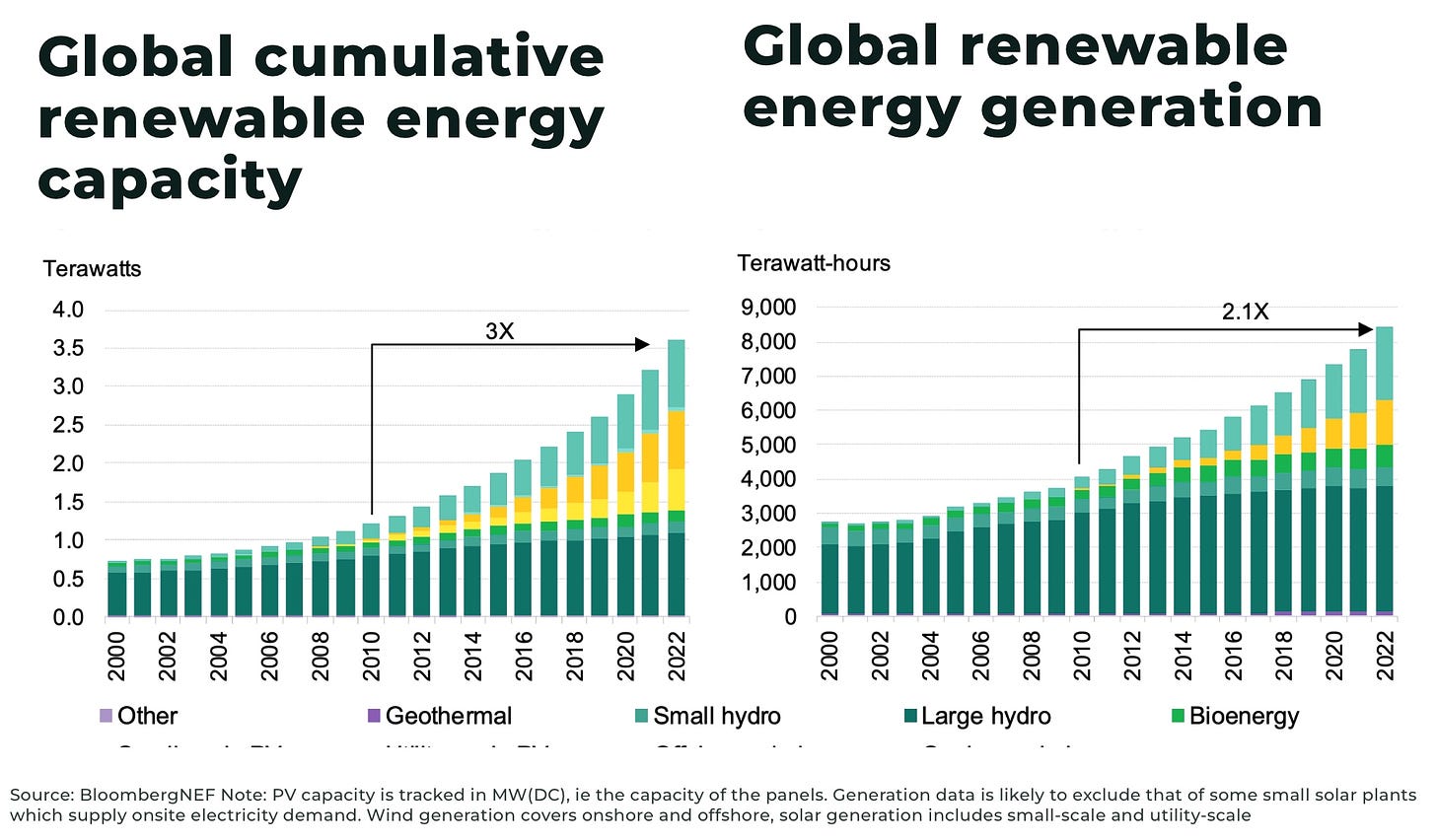

BNEF's Net Zero Scenario forecasts over 22,000 terawatt-hours of renewable energy generation in 2030, a 2.6x increase compared to 2022, driven largely by new wind and solar capacity

a 152 million km global electricity grid is needed to meet net-zero targets by 2050 — double the size of grid today. To put in perspective, this is the distance from earth to the sun

“The energy transition is the biggest long-term demand driver of tin. As this is in effect a switch from energy delivered via a pipe to energy delivered via a cable it will require increasing volumes of tin to join it all up”

— Wood MacKenzie, Tin – the forgotten foot soldier of the energy transition

All of this growth will need tin to allow electrons to flow. The challenge is supply.

Tin supply

In theory there are plenty of reserves of tin, but there are two major concerns over future growth:

tightening supply and lack of investment in new projects

geopolitical risk over current concentrated supply

In particular, the concentration of tin’s supply chains and reserves in volatile regions has meant investors are cautious about deploying significant capital in new projects.

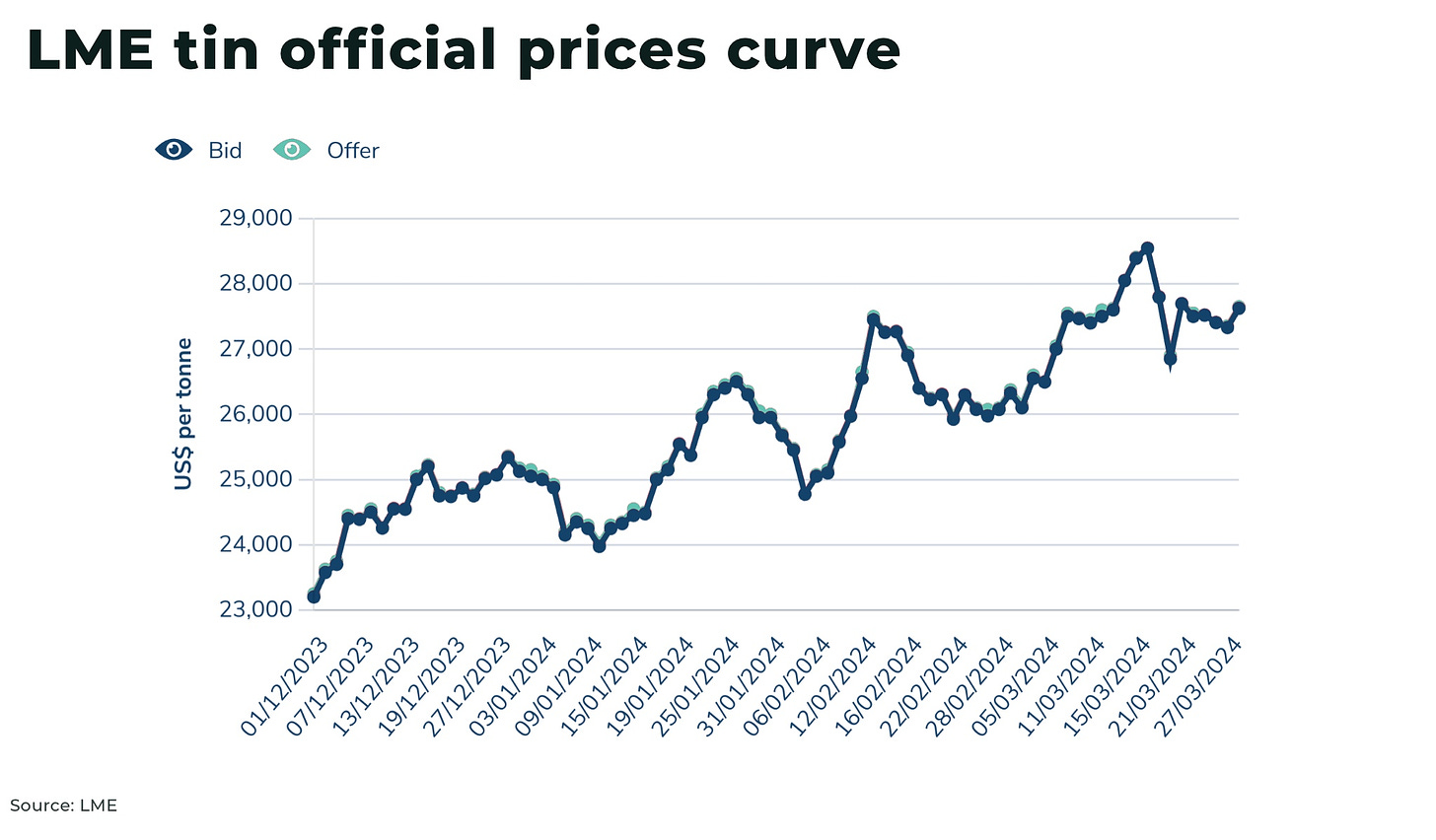

In March 2024, the price of tin reached the highest point in a year.

Tightening supply

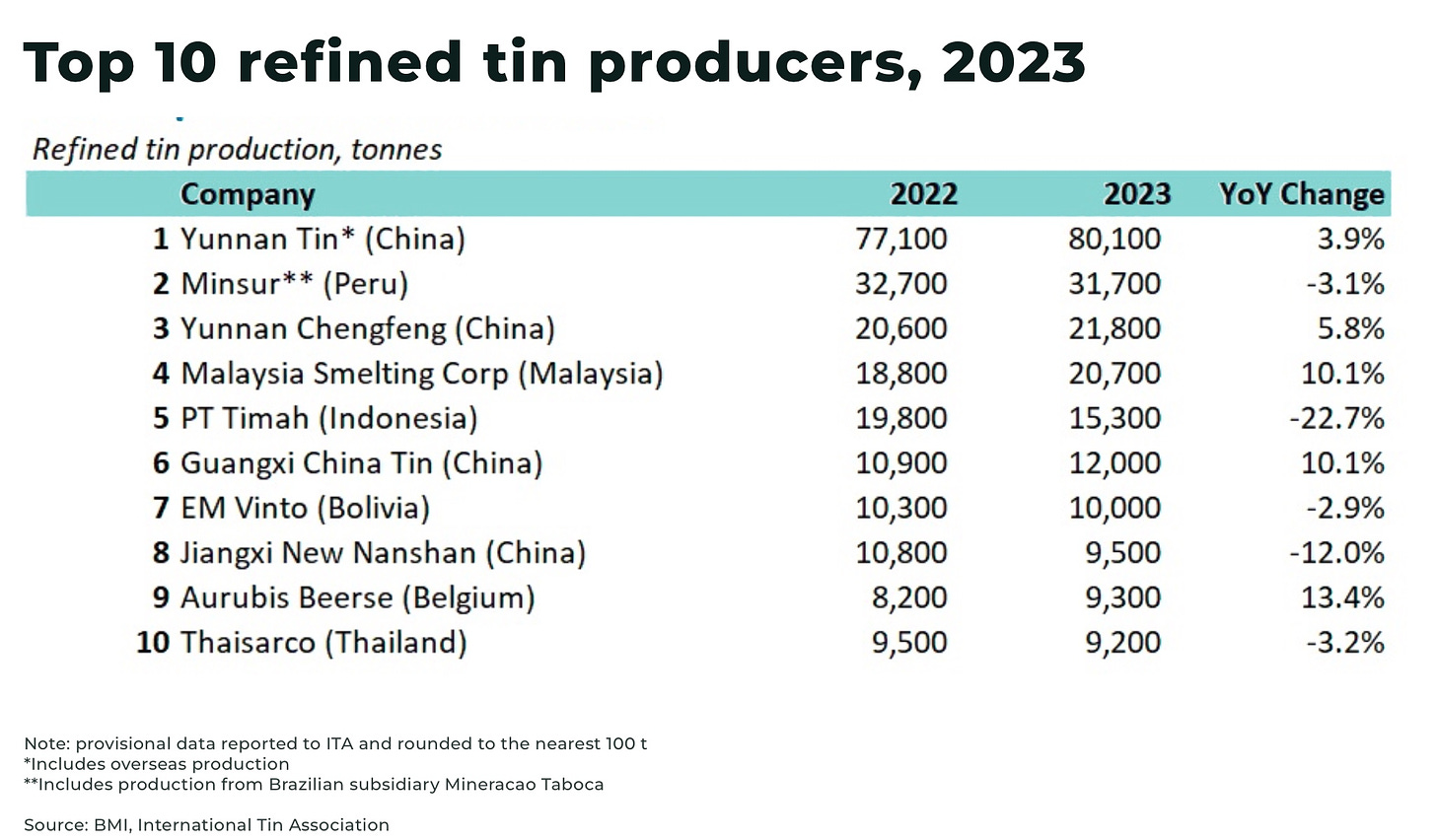

Global production of refined tin decreased 2.1% in 2023, from 2022, to 370,000 t.

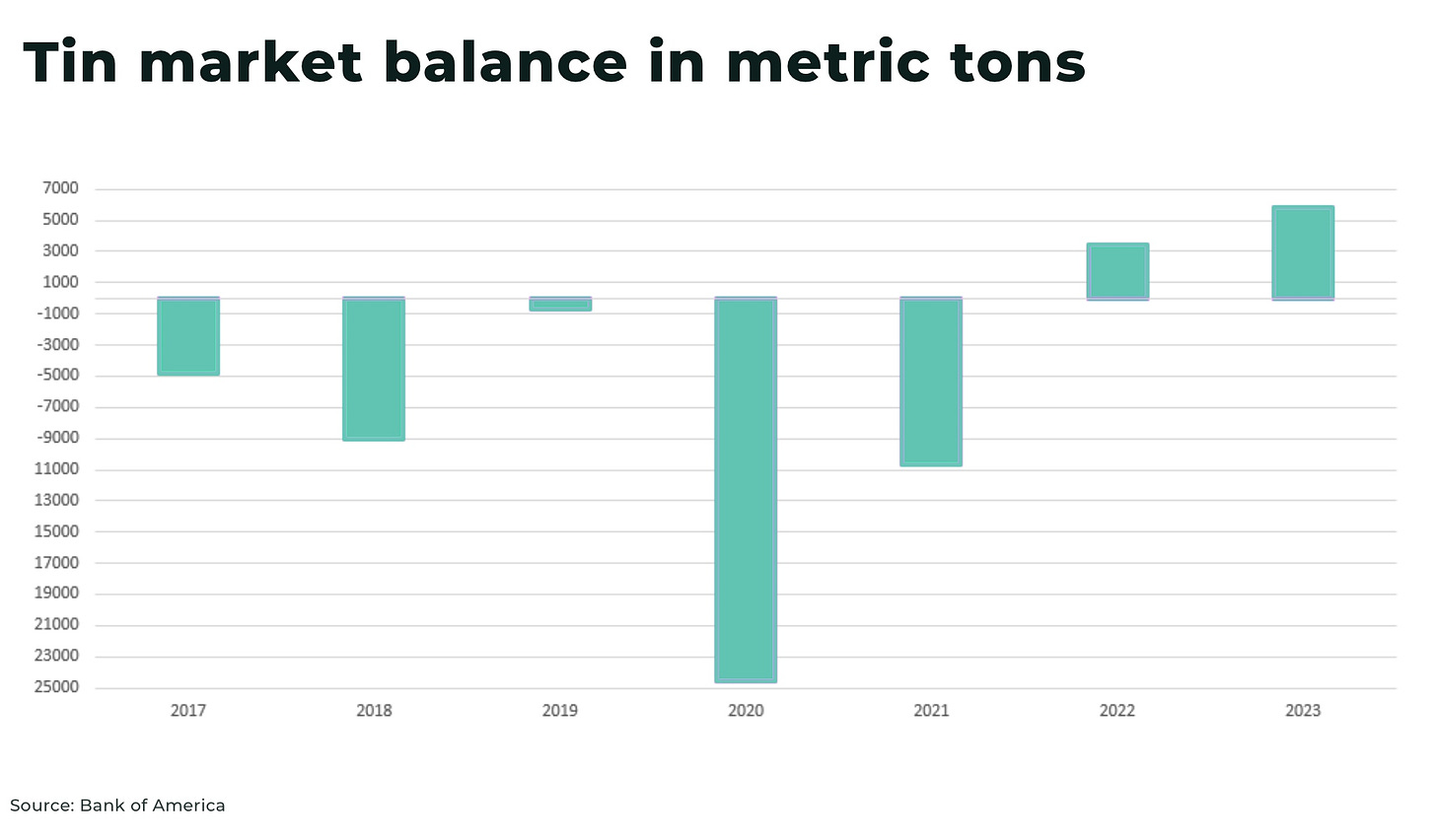

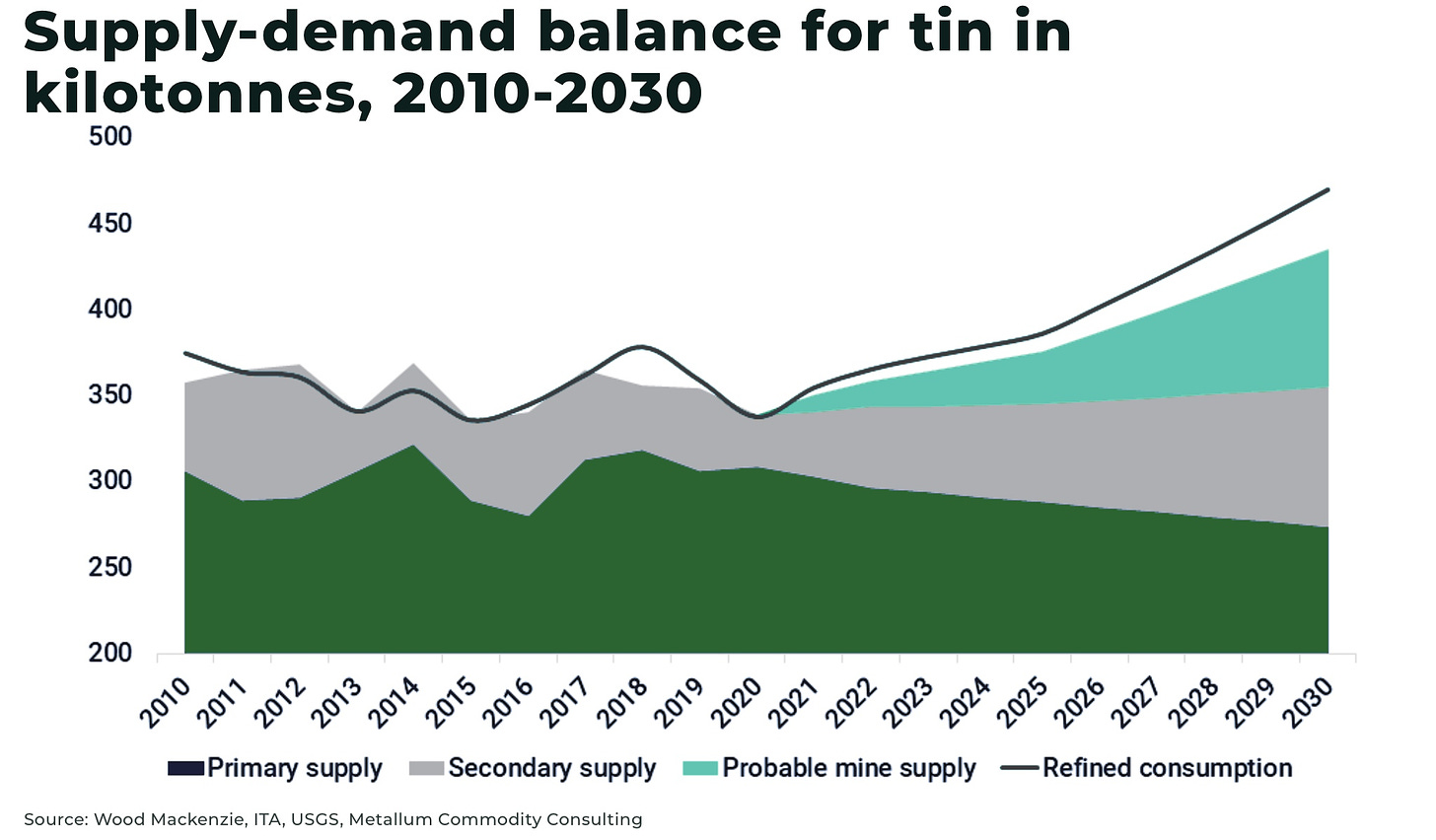

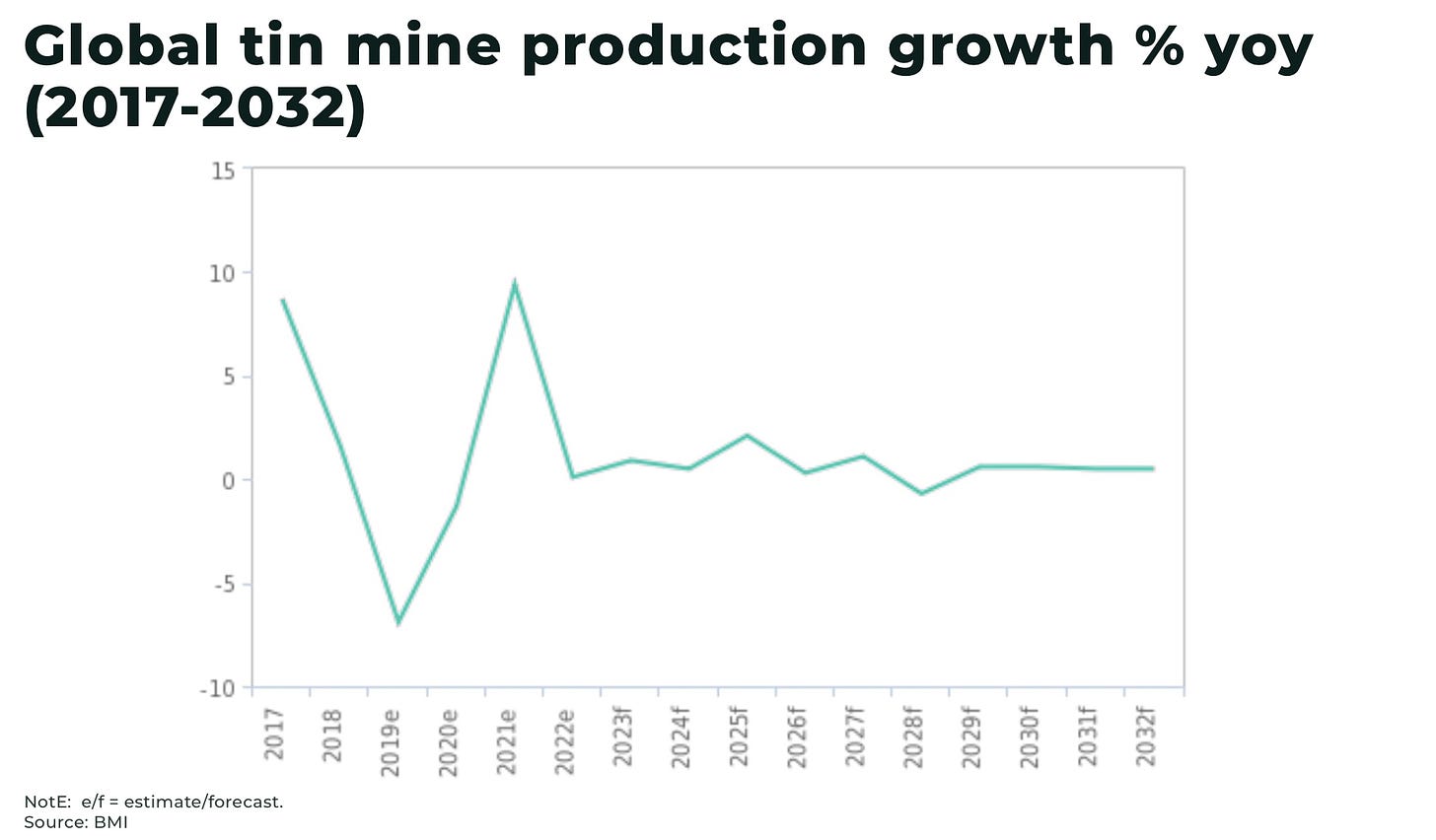

The tin market has run a deficit from 2017-2021, with supply forecast to fall 1% per year due to grade decline and reserve depletion.

The potential of tin supply to meet new demand is estimated to be limited to approximately 80 kt a year by 2030. It 2023 it's estimated to have grown just 0.9%.

Wood Mackenzie estimates growth in tin demand of approximately 3.5% a year which would mean supply will remain tight over the next decade, especially if the energy transition accelerates.

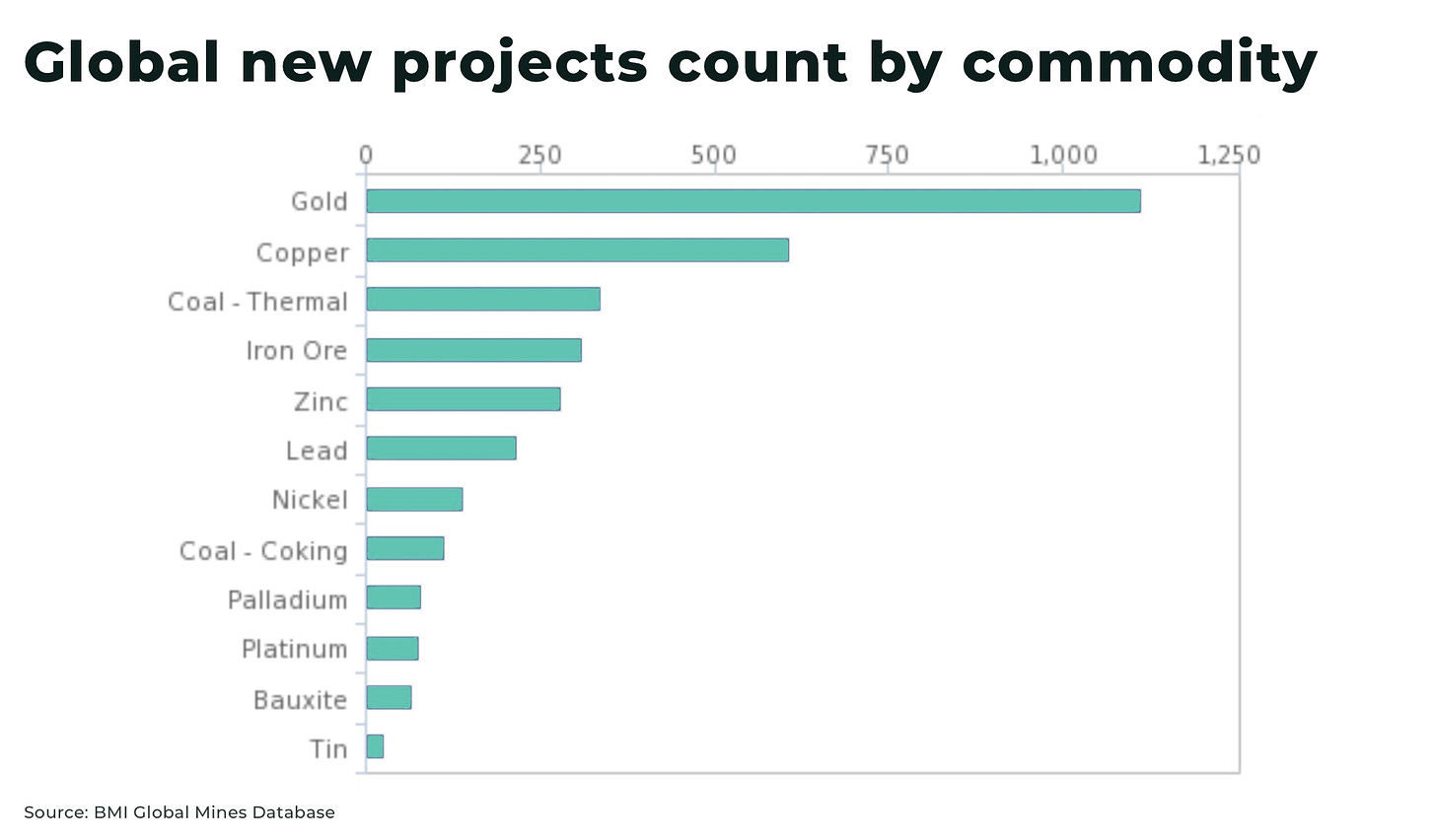

And there are few new projects coming online to relieve tight supply.

The International Tin Association (ITA) estimates just 11 new projects (and one expansion) are likely to be commissioned by 2030, providing an additional 35,000mt. But, like Wood Mackenzie, the ITA forecast the growth rate of demand for tin will double from its historical rate of 1-2% to 3-4%.

“We see tin use growth rates doubling from a historical rate of around 1-2% to more like 3-4%. Over the same period, demand is likely to grow more significantly than supply, leading to continued tight markets"

— James Willoughby, a market analyst with the International Tin Association, told S&P Global Platts

We have raised the alarm over the lack of investment in new mining projects for other critical minerals, but tin is almost in a league of its own with global tin mine production forecast to grow just 0.6% from 2023-2032, in comparison to 3.2% year on year from 2013-2022.

And, just like other critical minerals, with demand set to double, investment is needed now as it can take more than 10 years to develop a new tin mine.

Due to a global economic slowdown, there was a reported tin surplus of 9,700t in 2023, but any increase in demand with supply tightening could significantly impact prices.

Concentrated supply

59% of tin supply in 2023 came from just 10 smelters — and their market share increased by 856t.

Concerns, especially in the West, but also in China, over this concentration of supply is exacerbated by geopolitical risk.

China

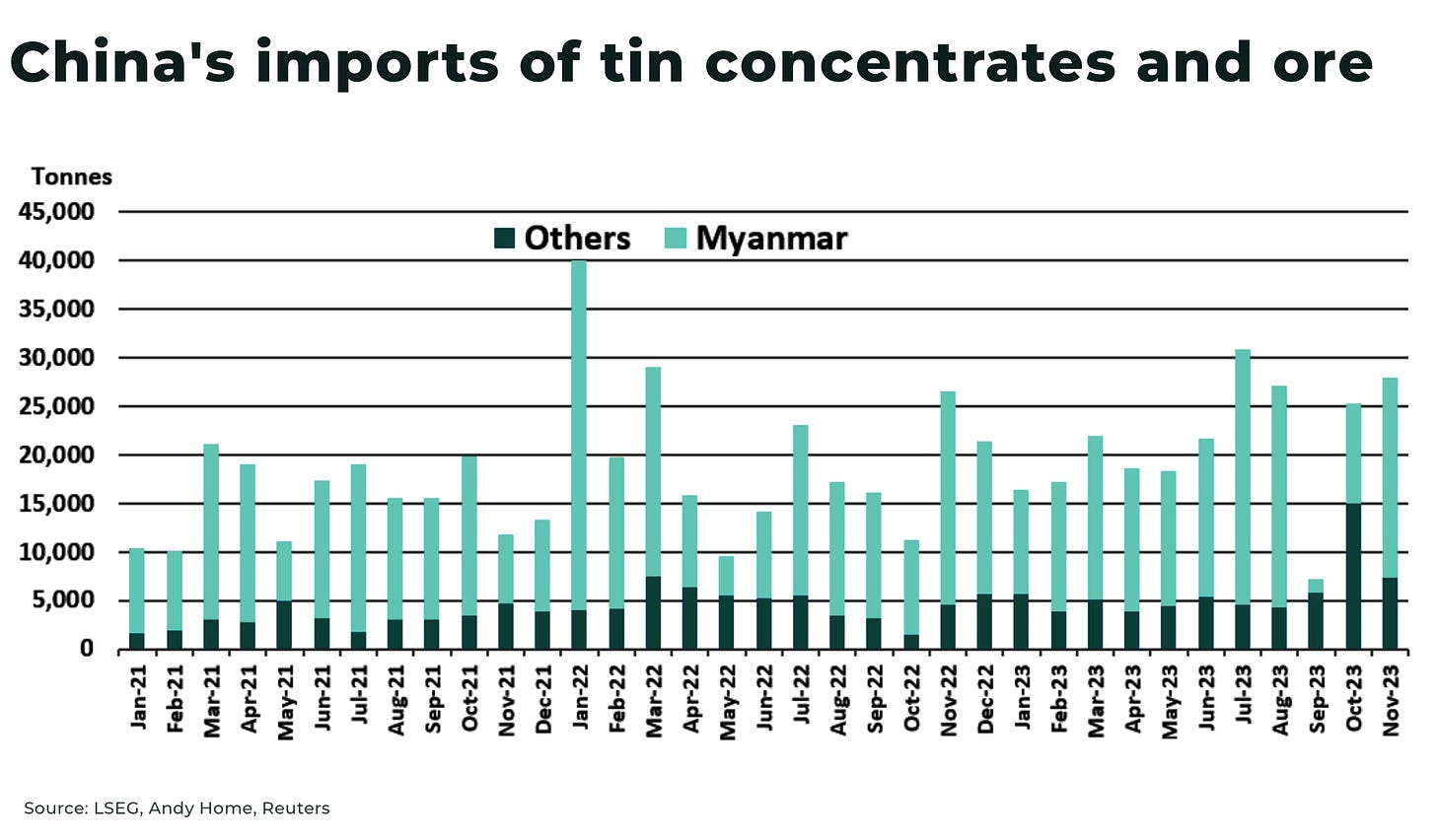

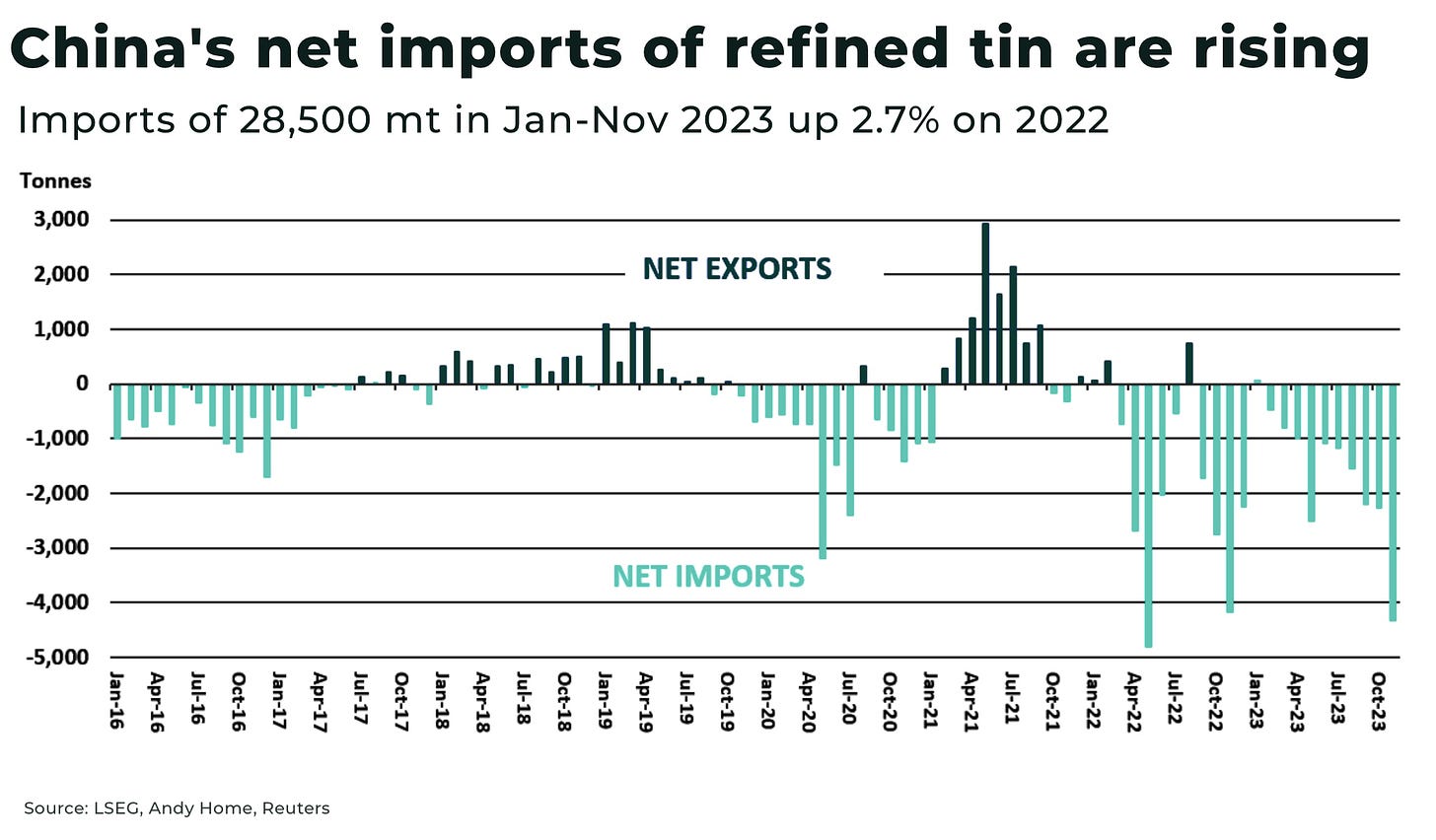

China represents approx 30% of global tin mine production and 50% of refining, but it is also heavily dependent on almost 75% of its imports from other sources in Asia, especially Myanmar, to meet demand.

Reuters reports that, in fact, stocks of tin in China are falling and imports rising — “suggesting domestic output is not matching demand.”

Total production in mainland China declined 1.3% to 177,000 t in 2023.

Myanmar

Myanmar is the world’s third largest producer of tin ore, but due to China’s dependence on its exports, it has significant leverage over the market.

In August 2023, Myanmar’s United Wa State Army, which controls Wa State (approx 10% of global supply, and more than 30% of China's supply in 2022) and one of the largest tin mines in the world, ordered a ban on all mining and processing operations for an extensive audit. The ban was lifted in January 2024 (with an increased export tax of 30%) — except for the Man Maw mine, the largest in the region.

The ban was reportedly well publicised and there has been significant stocking, but even if the shutdown is not prolonged, it could take up to 3 months before supply properly starts up again.

There is also an ongoing insurgency against the military government, with the acting president warning the country is in danger of falling apart after recent military losses. China has asked its citizens to leave the northern districts along its shared border with the country.

And it’s not just Myanmar.

Indonesia

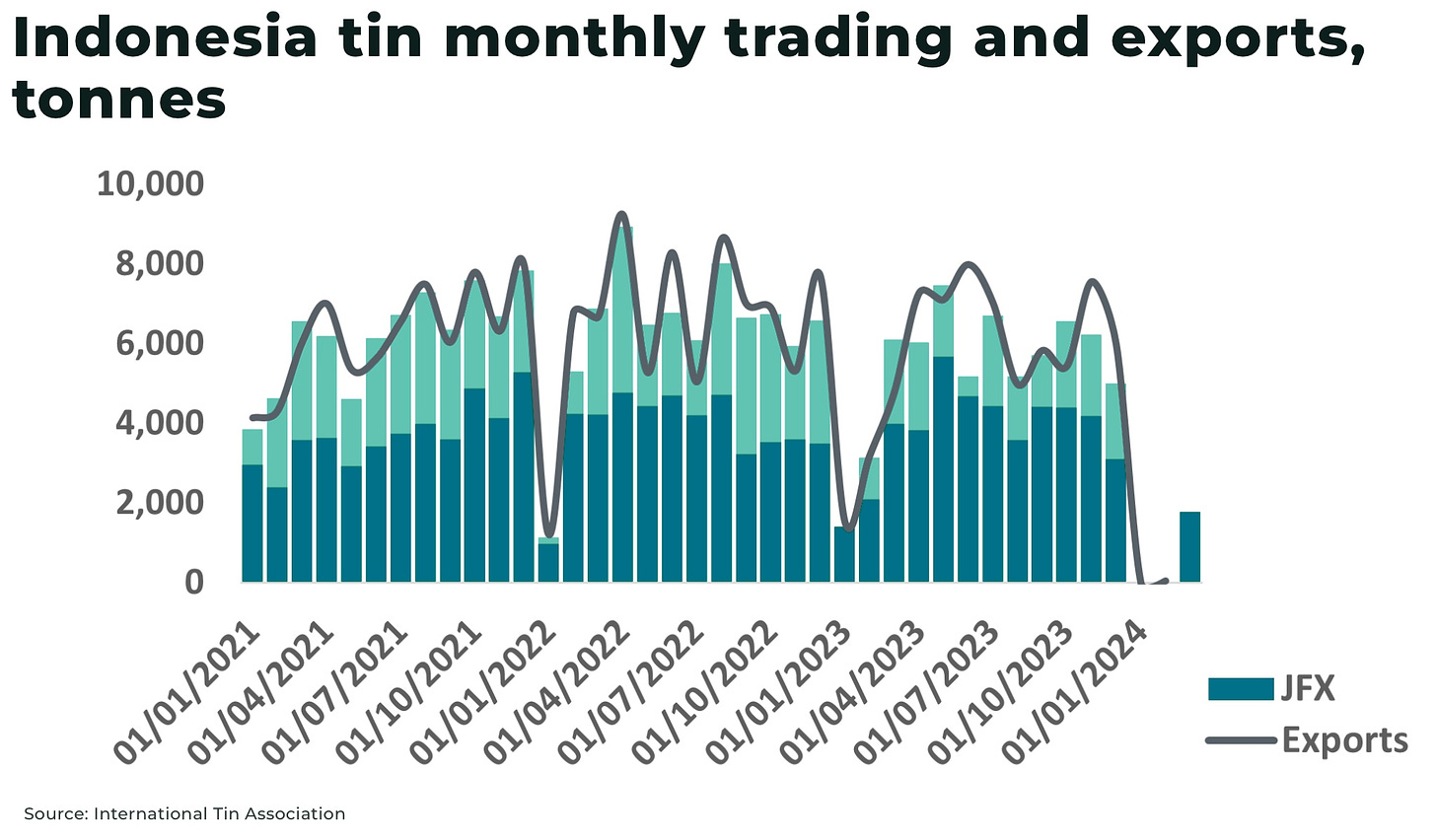

Indonesia is the second largest miner in the world and exported 78,000mt of refined tin in 2023, approximately 20% of global demand.

But a new government ban on exports of refined tin, due to a change in permitting, caused exports to collapse:

0.4 metric tons in January 2024, a 99% decline from January 2023, and the lowest level of tin exports since 2015

55 metric tons in February 2024, a 98% decrease from February 2023

In March 2024, some tin exports have reportedly resumed, with 1,780 tons of tin traded on various contracts. However, they are still comparatively very low with trading not yet resumed from some of the country's smaller smelters.

The ban has been implemented during a crackdown on illegal tin mining across the country, with arrests of major actors, including two company executives, which will likely significantly disrupt the industry's capacity to start back up to full capacity in the short-term.

It is also a similar strategy used by the Indonesian government to push resource nationalism, similar to their strategy to dominate the global nickel industry, and to encourage more downstream investment in the country's tin sector due to the metals' critical role in the electric vehicle manufacturing.

It is expected that exports will resume but the risk — or threat — from Indonesia to global supply is under the spotlight.

South America

The supply issues in Myanmar and Indonesia has meant Chinese smelters have pivoted to South America, with, for example, imports tripling from more than 8,550 tons in 2023 to 2,900 in 2022.

Peru, Bolivia, and Brazil make up an estimated 16% of world tin mine production. The US imported 27% from Peru and 21% from Bolivia in 2022.

However, South American supply is concentrated into a handful of major mines which are vulnerable to local protests. For example, Peru’s Minsur tin mine, the second largest producer in the world, suspended operations for two months last year due to protests.

Africa

Less than 4% of global tin mine production comes from the Democratic Republic of Congo (approx 9% of China imports), Uganda, Burundi, Rwanda and Nigeria. Mostly artisanal, small-scale mines, the supply is also vulnerable to local conflicts, from Kivu's ongoing conflict to sectarian conflict and lawlessness in Nigeria's Middle Belt.

Conclusion

The challenge for tin is not quantity of supply, but availability and security — especially for the West, and also (for once) for China.

There are significant global tin reserves (which could sustain markets for 50 years if exploited), we expect Indonesia supply to come back online, and in the immediate-term inventories have increased after the recent economic slowdown.

However, regional concerns over opening any new mines, as well as the threat of cheap supply from Asia has restricted investment in new mines, just as geopolitical risk from these very sources threatens to interrupt supply at anytime.

And, while China is set to remain the world’s largest producer until at least 2030, their ability to ramp up capacity seems to be reduced.

All of this is happening as tin’s importance across the AI revolution and energy transition only accelerates — the IDC expects annual growth of semiconductors to reach 20% in 2024.

"Against near-term headwinds, fundamentals look robust longer term on solar and electric vehicles... Tin demand from the green sector could more than double by 2030, potentially topping 70,000 tons per annum equivalent to a fifth of current consumption"

— Danica Averion, Commodities Strategist Bank of America, told Reuters

This is particularly important for the US policy of trying to secure its supply chains.

Tin has not been mined or smelted in the US since 1993 or 1989, respectively, making its supply chains vulnerable to geopolitical risk.

And, in March 2024, a 115-year-old US tin producer, Weirton tinplate plant in Virginia, was idled after the US International Trade Commission voted to overturn the imposition of anti-dumping duties of 2.69% to 6.88% on tin mill steel.

There are secondary supplies, but these are insufficient to meet demand, for example, the estimated value of imported refined tin to the US in 2023 was US$840 million, and the estimated value of tin recovered from old scrap domestically in 2023 was US$280 million.

There are an estimated 30 tin development projects across Australia, but only one operating mine, Renison Bell, a joint venture between Yunnan Tin Corporation and Metals X Ltd. It's unsure if it will be impacted by US critical mineral quotas to apply for the US Inflation Reduction Act electric vehicle tax credit.

“Looking into the next decade, the tin industry faces dramatic new market dynamics and ESG demands. It is important for us in the sector to understand what lies ahead so we can take advantage of the unprecedented opportunities and challenges… We foresee that the next decade will see a wakeup to tin with a new wave of efforts to secure a sustainably sourced supply”

Tin is needed to keep the energy transition and technological revolution soldered together, but what will keep the supply chains secure?

🚀 Please smash the ♡ button, subscribe for the banter ✓ and share with friends and colleagues. We are always grateful for your comments and support.

To get an understanding of the issue we need to go back in time, to the Bronze age. The Bronze age came about because of the discovery, mining, and refining of tin. Bronze is a mixture of copper and tin. Copper was mined in the ancient world in the island of Cyprus while the tin mines were in Afghanistan, tin was so important-it was the oil of it time-that however control it's trade had all the power and tech advantage. Today tin is not much though of but a world without it could bring about a collapse in economic activity akin to the collapse of the Bronze Age. The destruction of the tin trade was the contributing factor-along with climate-change, in fact the collapse of the Bronze Age is a detail record of climate change, the Seas People, and political mismanagement, the caused collapse of the Bronze Age. Using history as a guide I wanted to position myself to benefit from this structure deficit. Given that the market is small-uranium should service as an example-we should expect huge price swings. The WisdomTree Tin ETF-traded on the LSE-it is one of the few options available to profit.